Sustainability takes top priority for Lenzing Papier. We are committed to continuously improving our carbon footprint and are pursuing an effective strategy driven by efficiency, innovation, and environmental protection.

The Product Carbon Footprint as a Measure of Success

Der Begriff „Product Carbon Footprint“ (PCF) bezieht sich auf die Gesamtemissionen von Treibhausgasen, die im Laufe des Lebenszyklus eines Produkts, von seiner Herstellung bis zur Entsorgung, entstehen. Dieser Indikator gibt an, wie umweltfreundlich oder klimaschädlich ein Produkt ist und wird oft in Einheiten wie Kohlendioxidäquivalente (CO2e) gemessen. Der PCF ist entscheidend für die Bewertung der Umweltauswirkungen von hergestellten Produkten.

At Lenzing Papier, we are committed to minimizing our carbon footprint and safeguarding the environment. Lenzing Papier has its own deinking installation for waste paper, which leads to a significantly smaller Product Carbon Footprint in comparison to recycled paper grades, which have been manufactured by using Deinked Pulp from third parties.

Lenzing Papier's Secret to Remarkable Energy Efficiency

To attain our low energy utilization, we have invested in several measures. These include optimizing heat recovery with the help of thermocompressors, reducing steam evaporation and enhancing separation of ink from waste paper using special enzymes. Additionally, we are minimizing pump power consumption through technology upgrades and tight speed controls.

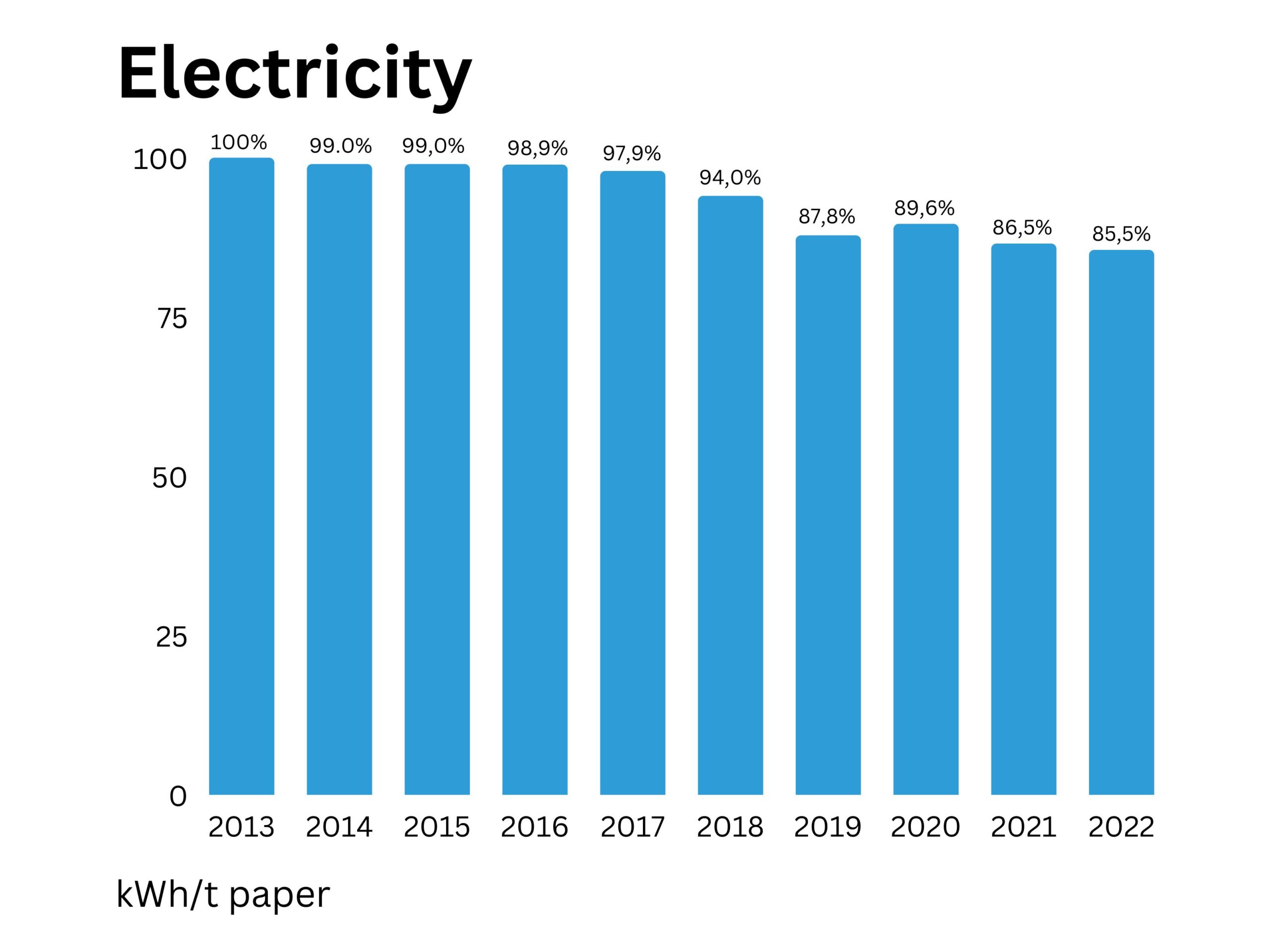

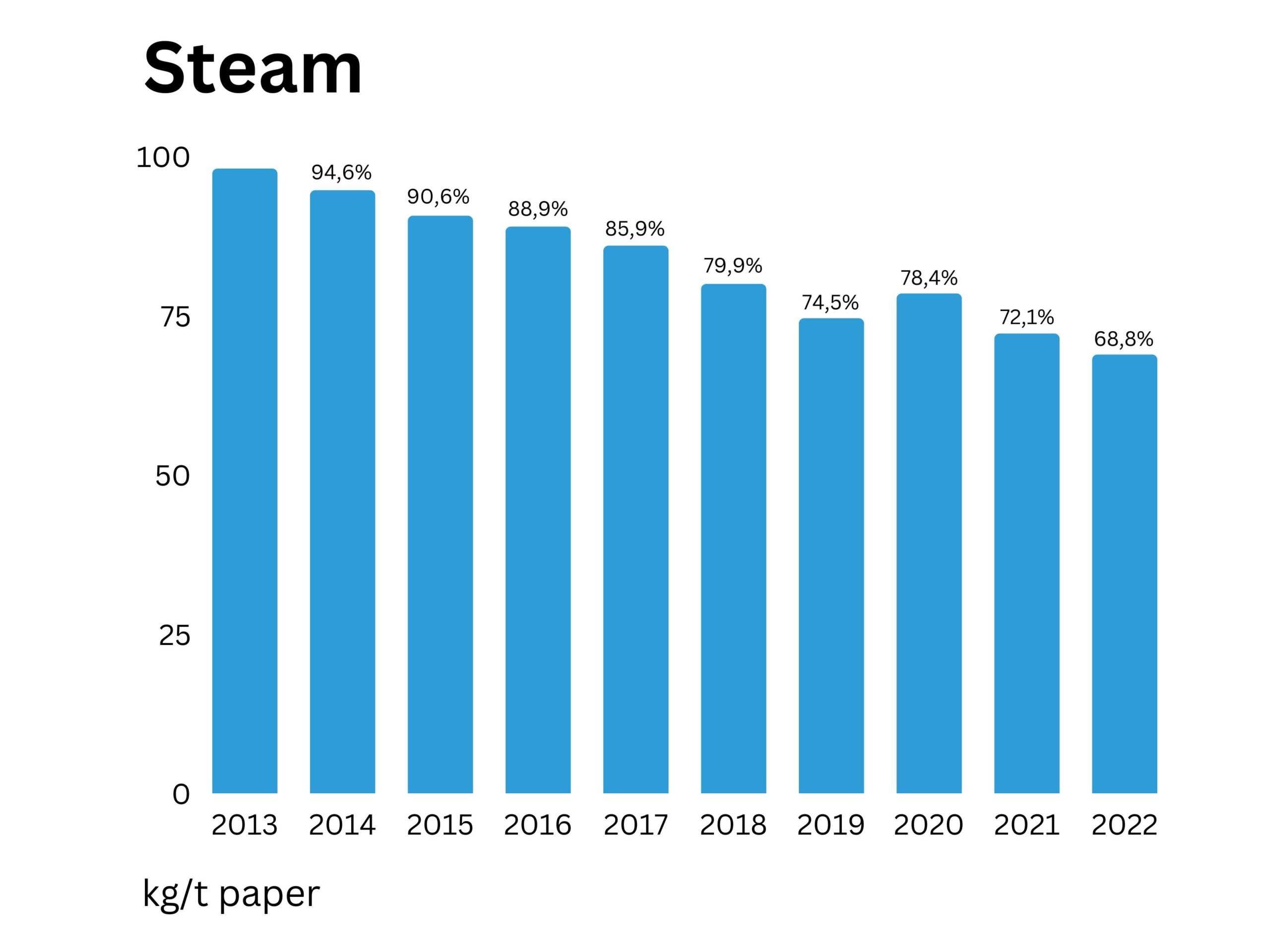

Success in Numbers: Reduction in Electricity and Steam Consumption

Unquestionably, the paper machine and the deinking installation are energy consumers. These two facilities account for 100% of the total steam and 95% of the electricity consumption of Lenzing Papier as a company. The sustainability efforts of Lenzing Papier are yielding clear results where it matters: in the production.

These two graphs illustrate the impressive progress in reducing our electricity and steam usage. The year 2013 serves as our benchmark year, and is referred to as 100%.

The development of efficiency measures to reduce steam usage reveals that steam requirements have been reduced by approximately 30% over the past 10 years. Similarly, a 15% reduction in electricity consumption has been achieved.

Sustainable Electricity Generation through Smart Resource Utilization

Lenzing Papier’s approach to electricity generation stands as a remarkable example of energy efficiency and sustainability. At a pulp mill located adjacent to Lenzing Papier GmbH, a byproduct of the pulping process, called black liquor, is burned in steam boilers. Often, this steam generated is a mere byproduct. Lenzing Papier cleverly utilizes this excess steam. Through advanced combined heat and power (CHP) technology, this steam is first used to generate electricity and thereafter used as a valuable heat source for the paper drying process. This intelligent resource management contributes to our supply of clean electricity and also significantly reduces the overall energy consumption of our company. It places us in a unique position, which is reflected in the extremely low Product Carbon Footprint in comparison to other paper manufacturers.

Determining the Product Carbon Footprint

Its enduring partnership with ClimatePartner, which started in 2008, has elevated Lenzing Papier’s sustainability efforts to a high level. At the core of this effort lies the calculation of the PCF (Product Carbon Footprint). These calculations are based on a precise analysis of emissions, fuel consumption, and energy measurements for each specific process step. The accuracy of these calculations and compliance with the highest standards is monitored annually by the Austrian inspection Agency TÜV.

For those seeking precise data and detailed figures, you can find the Product Carbon Footprint calculations for our individual products at the end of this article.

Lenzing Papier's success in the realm of sustainability is the result of a well-thought-out and consistently practiced sustainability strategy. The pillars of this strategy are on-site sustainable energy generation, integrated processing of raw materials, and continuous improvement measures. This approach enables us to provide recycled paper of the highest quality. Our products advocate sustainability and environmental protection.

Would you like to learn more about our sustainability efforts and our Product Carbon Footprint?

Contact us today and discover how the use of our premium recycled paper can help you reduce your carbon footprint and contribute to environmental conservation!

Downloads:

Product Carbon Footprint Produktgruppe Recyclingpapier Offset 1

Product Carbon Footprint Produktgruppe Recyclingpapier Offset 2

Product Carbon Footprint Produktgruppe Recyclingpapier Offset 3

Product Carbon Footprint Produktgruppe Recyclingpapier Offset 4

Product Carbon Footprint Produktgruppe Recyclingpapier Offset 5

Product Carbon Footprint Produktgruppe Kraftpapier Weiß 1

Product Carbon Footprint Produktgruppe Kraftpapier Weiß 2

Product Carbon Footprint Produktgruppe Kraftpapier Braun